Loading

Loading

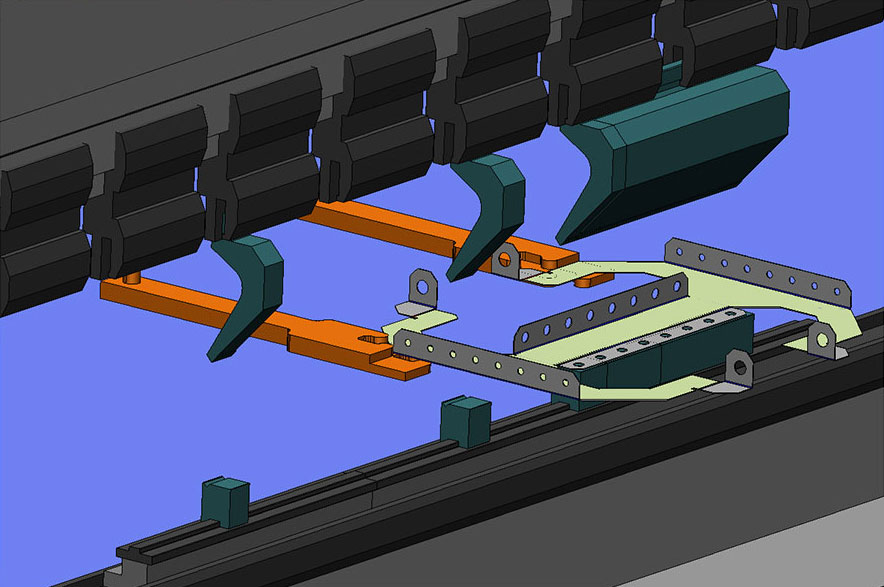

MBend is an application for programming and simulating CNC press brakes to maximize production resources. MBend enables offline calculation of tooling setups and bend sequences, with dynamic 3D simulation for avoiding collisions of the part with the machine elements.

Feature-rich MBend includes: