Loading

Loading

Tube Cutting

Tube Cutting

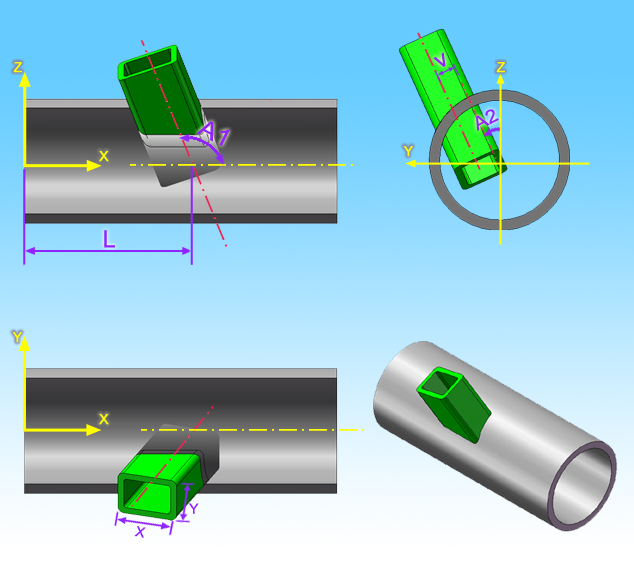

cncKad supports creating tube drafts, adding plane cuts or intersections between tubes and between a tube and a plane, creating tube nests, processing them, previewing ready tubes in 3D view, creating NC for your tube cutting machine, and simulating tube processing in 3D.

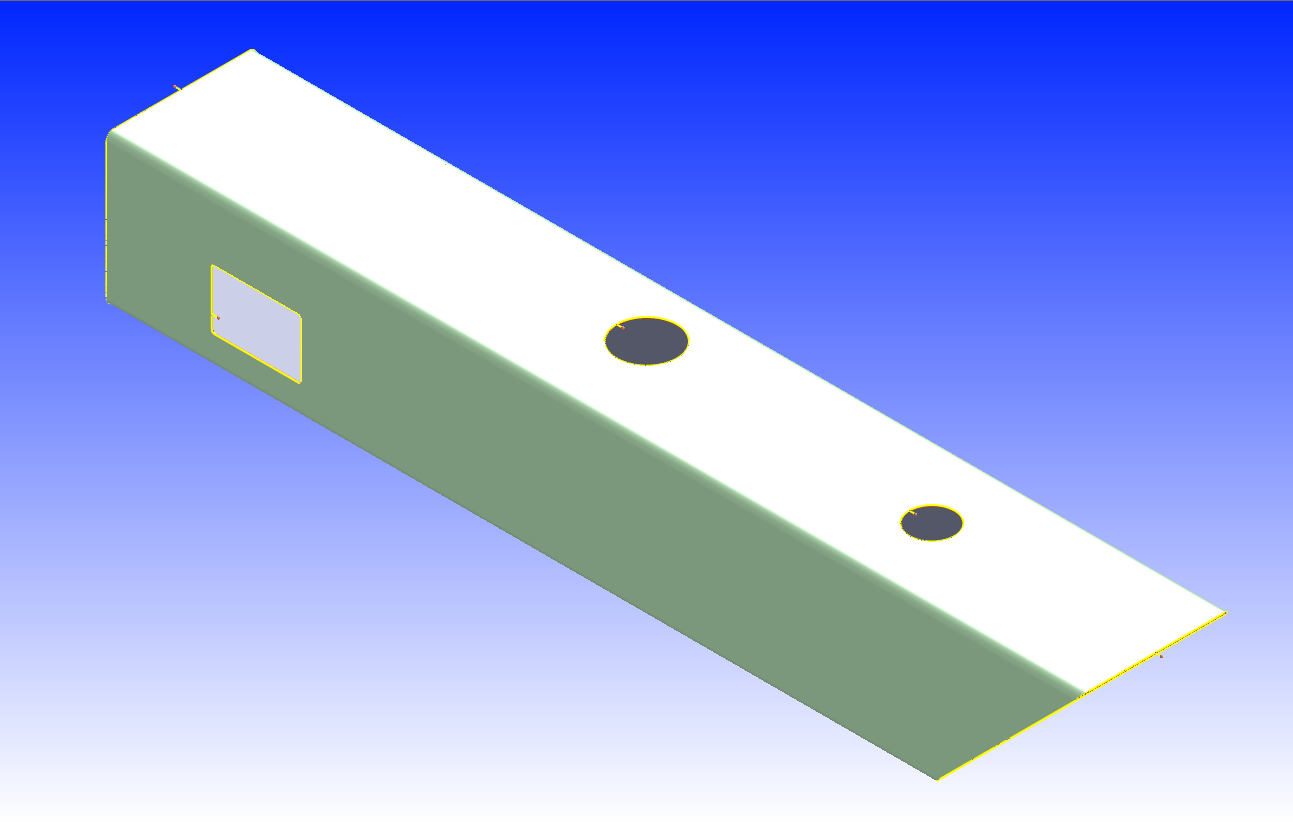

This construction was generated using cncKad’s tube cutting module

This construction was generated using cncKad’s tube cutting module

Processing

Processing

In cncKad you can create and process tubes of different shapes . For each tube profile you input the data such as material, thickness, and dimensions.

You can process any of these profile types:

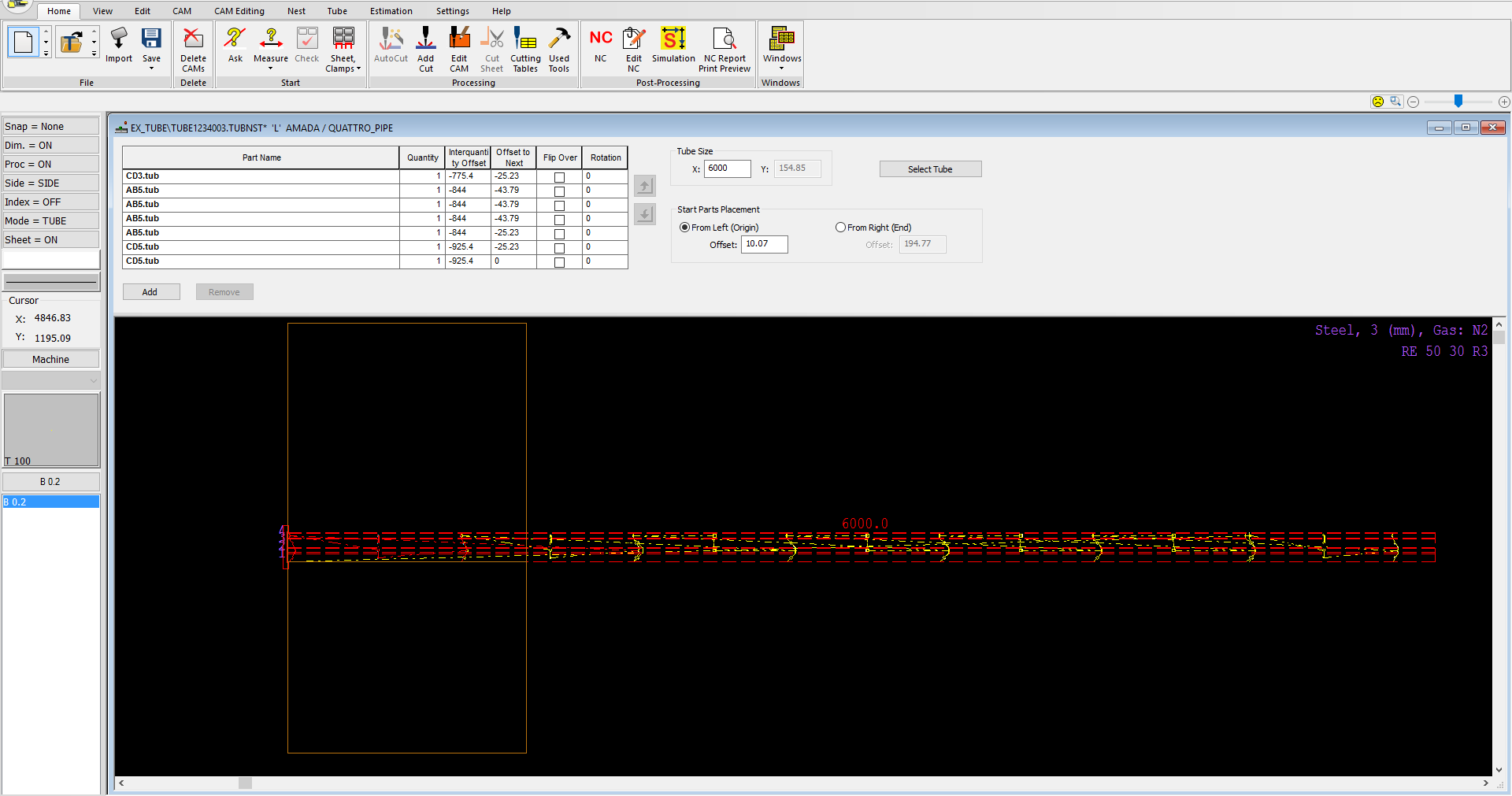

Tube Nest

Tube Nest

You can create tube nest, nesting your tube parts on circular or rectangular profiles of the same diameter, material, and thickness. You determine the number of iterations of each tube part, their placement sequence, spacing between parts, and whether the parts should be flipped and/or rotated.

After placing the tubes on the nest you can create common cuts for them.

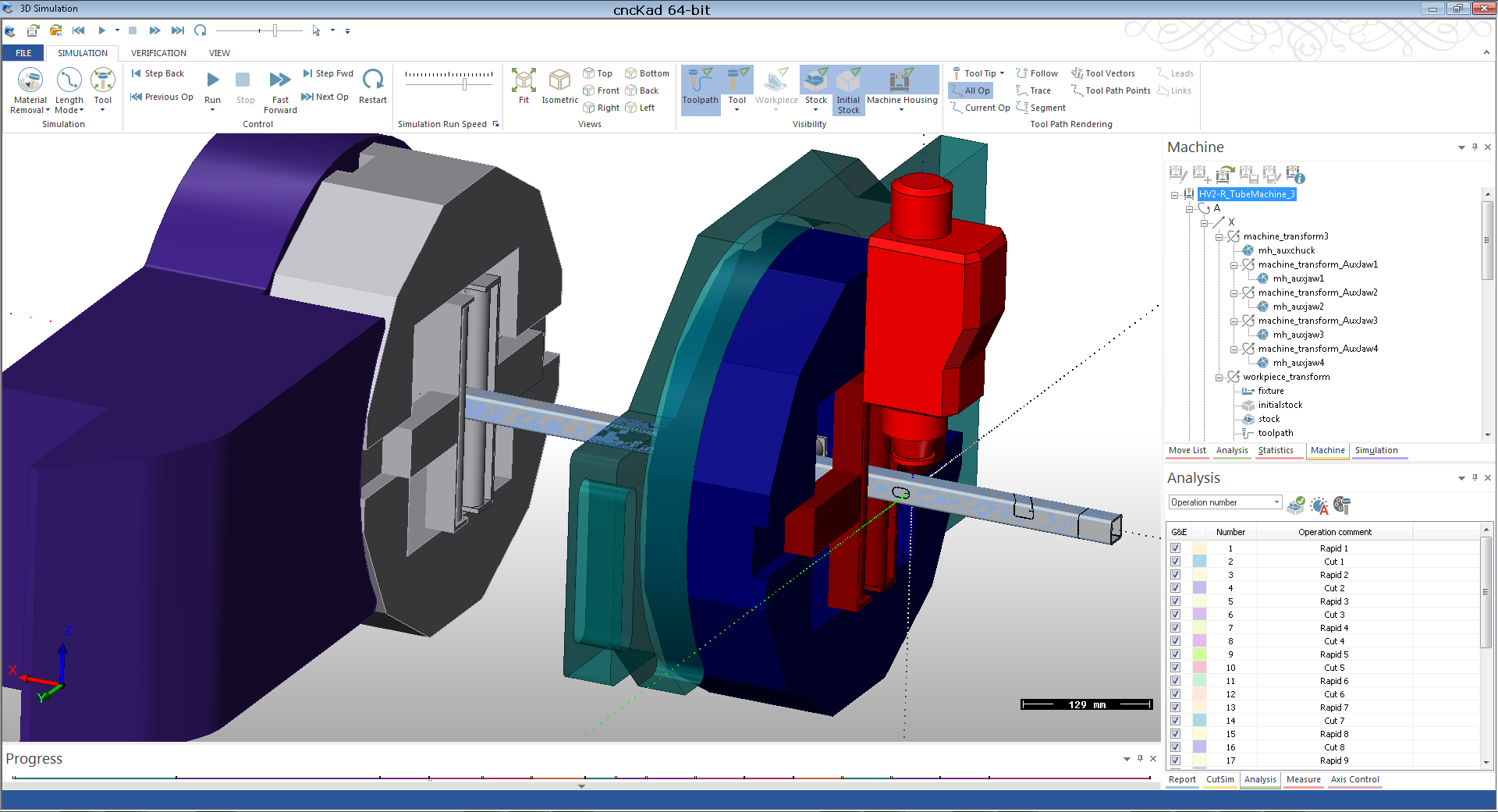

3D Simulation

3D Simulation

After processing the tubes and creating NC for your tube cutting machine, cncKad can simulate the NC codes. The 3D simulation displays tube rotation and cutting laser head movement.

This construction was generated using cncKad’s tube cutting module

This construction was generated using cncKad’s tube cutting module

Tube Link

Tube Link

Tube Link is a CAD Link for tubes. It exports a tube part or a tube assembly to cncKad from CAD software such as Solid Edge®, SOLIDWORKS®, Autodesk® Inventor®, Catia and PTC Creo®

For more precise geometry you can import the outer and inner surfaces.

CAD Link imports tubes to cncKad without flattening (unfolding) them, making the import process faster and less prone to errors. After you export the tube from 3D CAD software to cncKad, you can process the tube, nest it, place common cuts, create NC code, and simulate it in a 3D view.