Loading

Loading

Home / Waterjet / Gantry Machines / Waterline

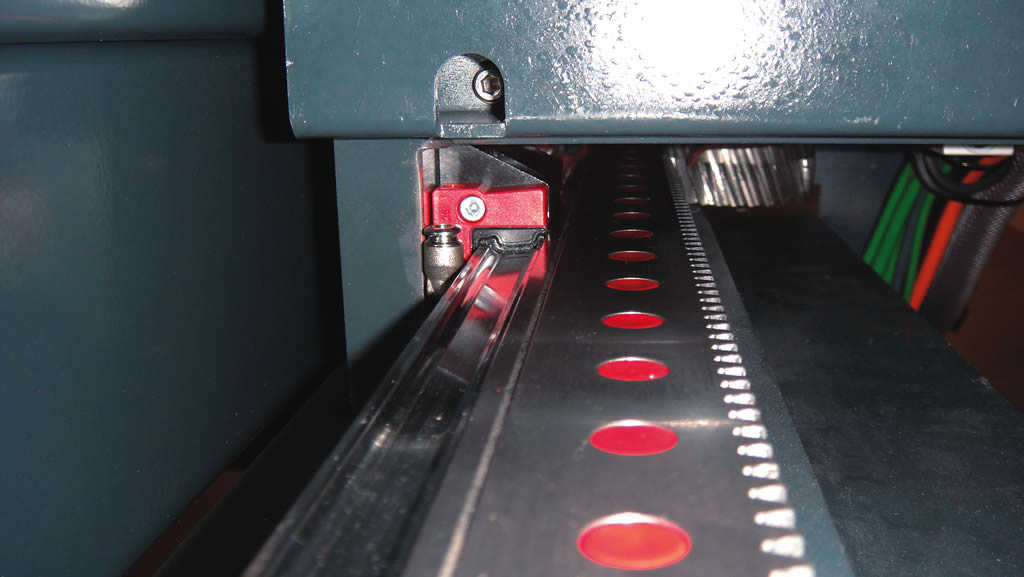

3 axis Gantry Bridge Technology with Integrated Tank and Helical Rack & Pinion transmission with self lubricating system.

| WL 510 | |

|---|---|

| Net Cutting Area | X = 3.400 mm (10’) Y = 1.650 mm (6’ 1/2) Z = 200 mm (8”) |

| Inner Table Working Area | 3.800 mm x 1.800 mm (12' x 6') |

| Overall Dimensions | 4.000 mm x 2.300 mm x h 1.800 mm (13' x 8' x h 6') |

| Rapid Speed | 0-20 mt / min (0 - 67’ / min) |

| Weight | 2.000 Kg (5.000 lb) |

| Position Accuracy | ± 0,15 mm (± 0,004”) |

| Repeatability | ± 0,01 mm (± 0,003”) |

| Ball Bar Ø 300 mm (12”) | ± 0,15 mm (± 0,004”) |

| STANDARD AVAILABLE MODELS | |

| WL 44 | 1.250 x 1.250 mm (4' x 4') |

| WL 512 | 3.400 x 1.650 mm (11' x 5' /2) |

| WL 612 | 4.000 x 2000 mm (13' x 5' 1/2) |

| Show All Data |

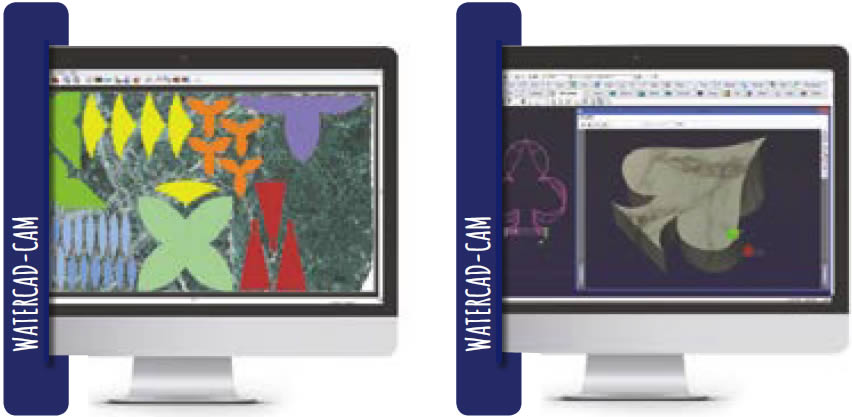

WaterCad-Cam is a CAD/CAM solution designed to easily automate the programming of Waterjet machines. Within the same program environment, you can design or import a part by DXF and DWG, consult the plate warehouse, perform manual or automatic nesting, execute manual or automatic cutting sequences, generate the NC program and calculate time and costs.